Regardless of where you sit in your organization, there is nothing more enlightening than meeting with customers – and even better, the end users. It is always an incredible opportunity to learn, and the feedback we get from users ultimately shapes our products and investments.

If you work in the product development organization, like me, then it’s even more useful.

Broad portfolios help customers grow

As a software company, it’s important for GE Digital to stay ahead of the technology curve, but even more important that we meet our customers where they are and help them along the journey.

To drive real results for our customers we have to put the Industrial Internet to work. Anyone can throw around trendy jargon about the next big thing, but real, sustainable change isn’t achieved with one-off data science projects.

6 Lessons Learned

To be successful, the power of digital solutions must be combined with industrial expertise and applied to specific challenges that show early returns and scale over time. Our customers and users reinforce this for us. Here’s what they say:

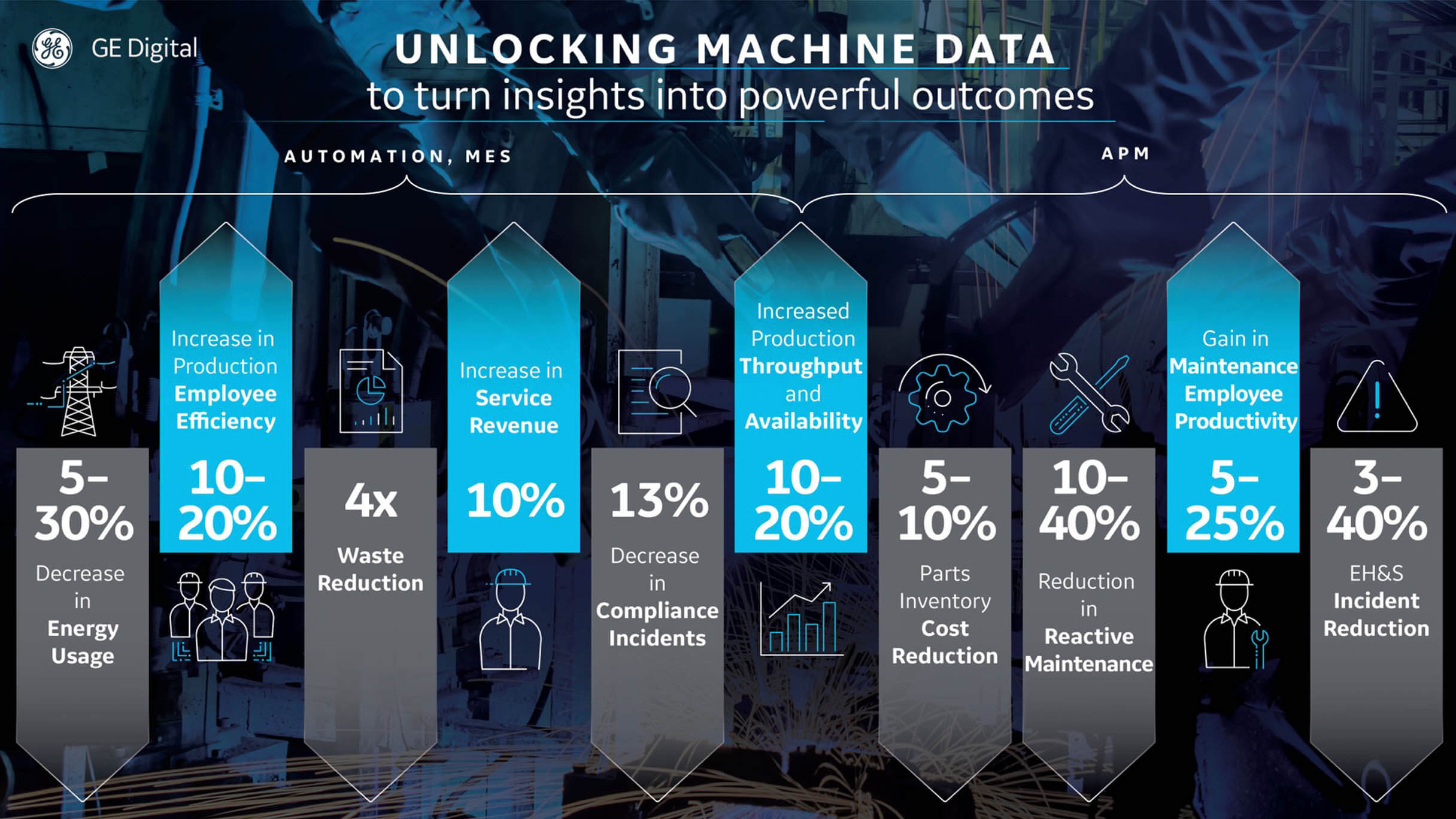

- It’s still all about outcomes. IIoT software is built to solve problems, and customers want to see how their investment will lead to improvements in their KPIs before they deep dive into the technology – no matter how differentiated it may be. Using software from across the portfolio can release a much greater set out outcomes.

A broad portfolio can drive many real business results

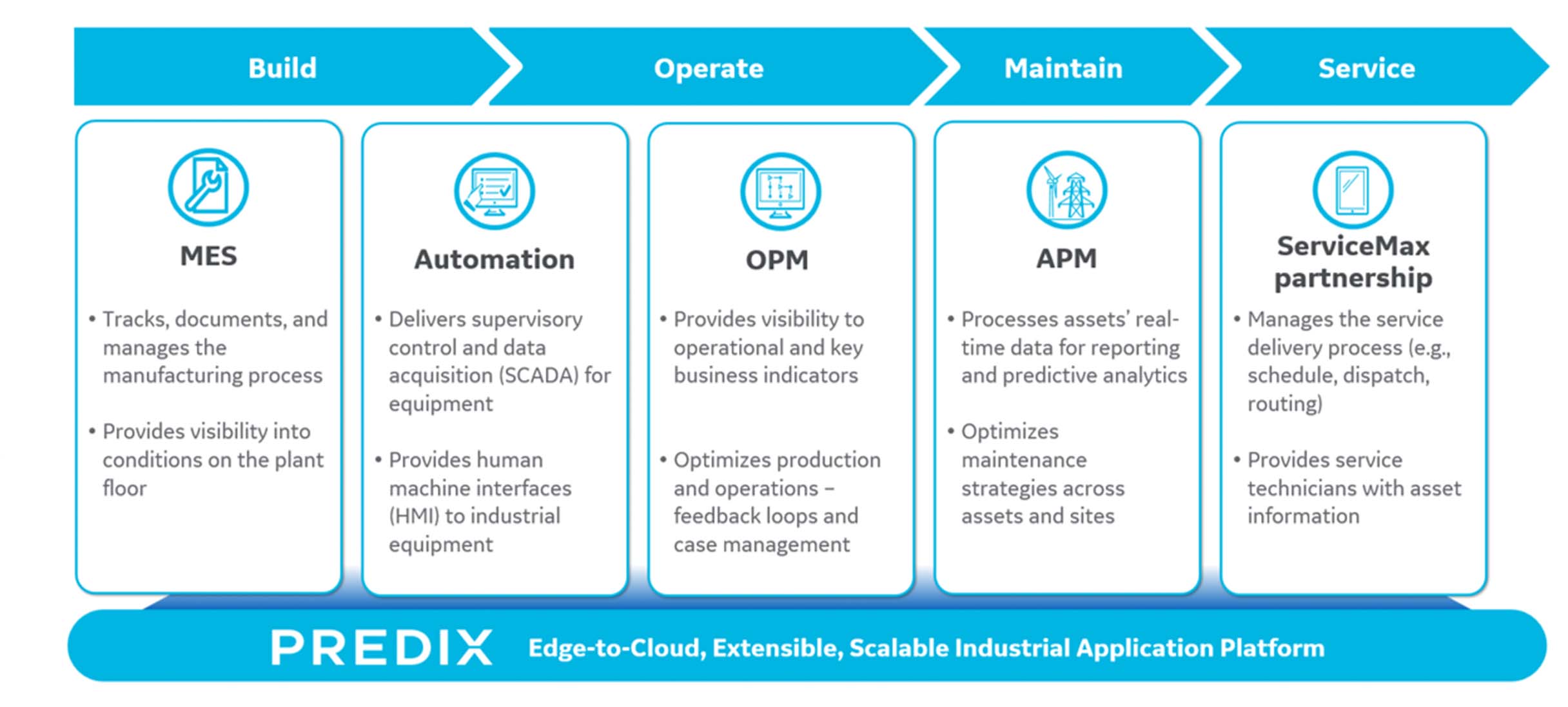

- Having a portfolio of strong, interoperable technologies– and being able to clearly describe that portfolio – is mission critical. Customers might have HMI/SCADA solutions today and now want to visualize that information in new ways. Some are developing connectivity solutions not recognizing that we already offer it within the Predix Platform. One customer was delighted to discover our new Predix Manufacturing Data Cloud (Predix MDC) offer – used by P&G at dozens of factories around the world– because he could stop his team from trying to design the same solution from the ground up.

- Putting the industrial Internet to work is a team sport. We are investing across our portfolio of products – HMI/SCADA, MES, APM and OPM, and underpinning them with our edge to cloud Predix Platform. But we can’t grow without our customers’ feedback. Our focus on making features and functionality counts for a lot, but ultimately that functionality needs to solve our customers’ problems day in and day out.

How our products “greet” our customers is an essential consideration. Customers loved our new application interfaces – the clean, simple dashboards, and most importantly – that the operators using the products every day find them powerful and useful. It’s a somewhat cliché term, but it reinforced the point that in many cases, the voice from the shop floor is more important that the voice from the top floor.

- Customers want to know what’s next… There is great excitement about Predix Operations Performance Management (OPM).While our well established Predix APM software applies AI/ML to machines to predict when they might fail and the best time to take predictive maintenance activities, Predix OPM does the same for processes, providing fleet and operations-level insights that brings many disparate bits together in one centralized view. Already being used in the power industries, we see OPM as a huge opportunity for manufacturers as well.

- Our clarity and commitment to product roadmaps has never been more important. We are investing in a focused way across our portfolio and building on our product heritage in a way that helps customers progress at a pace they are comfortable with, unlocking new value and reinvesting as that value increases.

Our teams will continue pushing ahead on product releases and helping our customers put the industrial internet to work for them.

GE Digital, Putting industrial data to work.