Definition

What is digital transformation?

Digital transformation is the process of creating a connection between physical operations and physical science, data, and advanced analytics to solve business problems and enhance operations. This journey of transforming businesses from manual to digital workplaces is establishing a new era of new working processes, culture and customer experiences.

At GE Digital, we provide a range of tools, techniques and software applications to support you along your digital industrial journey, created with years of experience enabling digital transformation for businesses across industries and markets.

From services to help you map out a digital industrial blueprint, to our GE Digital Foundries around the globe, designed to bring teams together to define outcomes using capabilities such as design thinking, data science, and a team of engineers and GE domain experts.

Whatever your needs, continue reading to learn how digital transformation can revolutionize your operational capabilities.

Benefits

Digital transformation can benefit your business

Taking steps to transform your business digitally is complex. It requires change across people, processes, and technology. However, successful implementation of a digital transformation strategy can allow you to solve your business challenges, enabling you to hit targets, reduce your operational costs and reduce time to value.

The benefits of digital transformation include:

- Exceed targets: Automation enables information sharing across multiple locations in minutes, not days and weeks, while simultaneously reducing costs through optimization

- Remove operational challenges: Automation allows for the reduction of steps and admin in operational processes, enabling smoother and faster operational efficiency.

- Reduce total cost of ownership: Taking a digital-first approach to business operations allows for the elimination of paper and manual data hand-offs, instead making data and organizational capabilities available to all users; whenever they need it and wherever they are.

- Reduce time to value: Deliver value to users and organizations rapidly, using agile delivery approaches and leveraging the cloud to simplify deployments.

- Automate manually intensive tools and processes: An integrated software solutions portfolio of your connected network model data can be orchestrated across the enterprise, to drive efficiencies in your operations throughout the asset management cycle.

- Connect disparate and siloed data: Traditional ways of operating in siloed departments are no-longer sufficient. Without a single, current network view and the ability to integrate it across the organization—everything you do becomes more expensive and time-consuming.

- Positive culture change: Embracing digital transformation is an important step towards being future-ready that sends a clear and positive message that, in-turn, stimulates a refreshed forward-thinking culture across your business and stakeholders.

Why are businesses experiencing a digital transformation?

Transformation of any sort requires a clear understanding of your current limitations, a vision of what the future organization looks like, and a constellation of executive buy-in, financial support, new organization models, and a change management system that drives a new mentality to every employee. A holistic approach is vital to seeing this through, and ensuring digital transformation is a long-term endeavor that delivers sustained results.

Businesses have to ask and answer some tough questions to understand and evaluate the specific requirements of their digital transformation – there is no one-stop-shop:

- Where are you in your digital transformation journey?

- Is this an enterprise digital transformation or more of an “innovation group-driven effort”?

- What conversations have you had with various product lines about how they would like to work on this digital transformation?

- What does success look like to you and your leadership?

- What’s not working today?

Based on our experience, there are three fundamentals to success that we urge aspiring digital industrial companies to organize around:

- Make sure you can fund the journey. Start by identifying areas of quick wins that will demonstrate short-term value and results. Look for cost and revenue opportunities, and a simple organizational structure that is agile and can adjust quickly.

- Plan for the medium term. Identify areas for growth, new business models, or target an operating model to improve.

- Finally, organize the transformation initiative for sustained performance. This is a significant step toward becoming a digital industrial company. Both short-term wins and medium-term innovations can help provide the needed credibility among leadership to advance the initiative forward.

The roadmap

Creating a strategic digital transformation roadmap

Prioritization framework

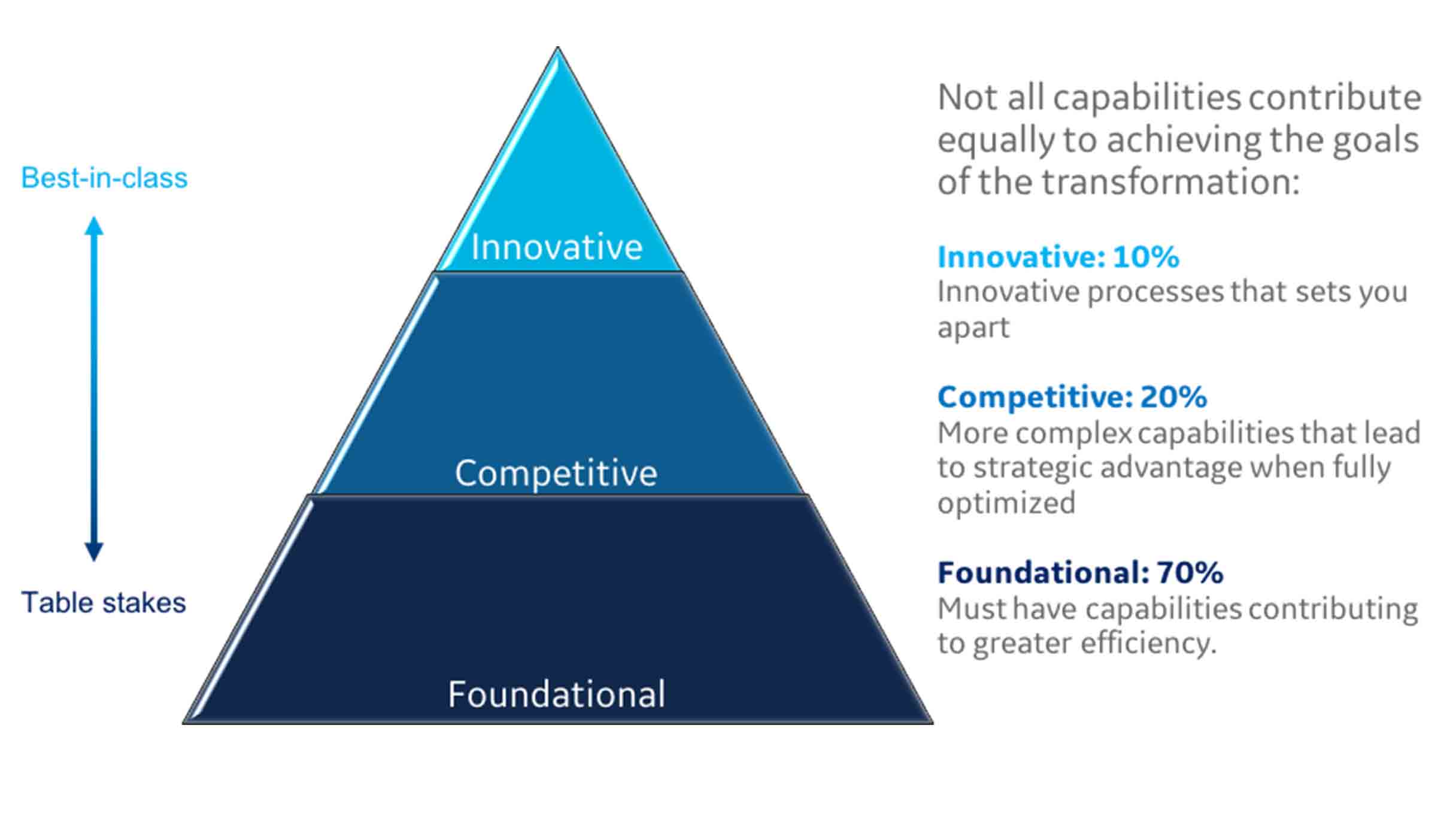

As shown in Figure 1, not all capabilities contribute equally to achieving the goal of a digital transformation, and hence need the highest attention of the transformation executives and focus within the digital transformation roadmap.

About 20% of the capabilities are must-win, or the ones that give you a strategic advantage. However, only 10% of the capabilities are truly innovative — things that will set you apart. Often, these are also the hardest to set up, and require significant time, energy, resources, and commitment from the leadership. They are often built by creating teams dedicated to constructing these capabilities as part of the digital transformation roadmap.

70% of the capabilities are foundational. These typically drive efficiency, and most of the time, these are the easiest to implement, and need less direct oversight. In addition to determining the capabilities that are strategic to the digital transformation, you also have to assess where you are in the maturity of those capabilities. You don’t have to be best in class in everything that is important.

Successful transformations focus on capabilities that will differentiate the business and drive competitive advantage.

Avoiding pitfalls

One of the key learnings from implementing our internal digital transformation was that it is critical to formalize your vision. Now is the time to think BIG. Identify and pick up your quick wins. Then, scale those quick wins through a digital transformation office to sustain momentum. Finally, assess and build capabilities from Day 1 across business units and P&L centers. Here are some additional key learnings from GE Digital’s journey that can help lay the groundwork for success along your digital industrial journey.

- Recognize the importance of target capabilities, and think about systematically incorporating them in transformation.

- Emphasize cross-functional and business unit coordination. Developing robust capabilities involves new talent (supported by HR), new tools (IT), new processes (operations), and new governance (leadership).

- New capabilities might represent a huge shift into the unknown.

- New capabilities call for fundamental change in behavior

Riding the maturity curve

Remember, capabilities are one key aspect of a digital transformation. Let’s focus back on the 30,000-foot view of the outcomes driven by the adoption of digital techniques, and the increasing maturity and impact of the transformation. We encourage all businesses considering a digital transformation roadmap to start with the same early focus: driving productivity in existing operations.

By focusing on delivering tangible ROI today through productivity improvements, you get three things:

- The ability to self-fund the next step in your transformation journey—such as new product introductions.

- The first steps in building-out the operational agility needed to innovate at the business model level.

- The ability to build early internal champions, and the momentum needed to drive more radical transformation.

Building credibility is the key to any successful transformation. Internal productivity is much easier to achieve than being “the next big thing” outside of the four walls of your company.

With the data, insights, and improvements from these internal wins, you’re now in a credible position to take those same productivity improvements to your customers, in the form of best-practice sharing, or even as new products and services. This is what we have done, and it’s part of GE for customers.

Once established, and you have a repeatable line of sight into the outcomes you’re able to achieve, you are in a position to start the dialogue around new business models that leverage this data and connected infrastructure. These lead to marketplace concepts like application economies around your offerings.

The different maturity levels of your digital industrial transformation will involve a sustained focus on capability development to take the successes and scale them.

The capabilities that will be foundational, competitive, and innovative at each level of maturity are different. Organizations striving for differentiation should continue to keep a capability focus, and effectively manage change to build those muscles.

Finally, organic development, investment, and acquisitions have traditionally been strategic levers that organizations can pull to enhance capabilities. In today’s world however, where open innovation has come of age, focus instead on building key partnerships that can help you close your capability gaps faster to ensure maximum effectiveness.

Looking ahead

Digital twins, artificial intelligence (AI), machine learning, predictive maintenance, cybersecurity. These are just a handful of digital transformation opportunities, challenges and technological tools that currently exist in the market.

These aren’t just buzzwords, though. These are digital concepts and technologies that can create real, new value for businesses. The potential of digital transformation is huge, and many industry leaders see demonstrable value from them already as they connect machines to the Industrial Internet of Things (IIoT).

Cost savings, improved productivity, reduced waste, optimized maintenance processes, new business models and improved customer service are all in the mix when it comes results. So how do you get from here to there? The path to unlocking new value typically includes three key steps:

- Connect and digitize for purpose-driven productivity. This step allows you to develop real-time visibility into asset performance across devices. With a thoroughly connected and digital-oriented enterprise, you can begin to capture more data and make it actionable.

- Optimize operations and market engagement. You can now use your data as a differentiator—leveraging relevant real-time insights to reduce delivery time and increase throughput, for example. It’s about getting visibility into plant operations, boosting productivity, enabling flexibility, accelerating time to market, and meeting customers’ needs.

- Innovate and scale new business models. Take things to the next level with machine learning and AI, allowing you to enable value-based service differentiation and pricing. One example: Leveraging advanced technology to optimize maintenance schedules and anticipate potential downtime before it happens.

GE Digital’s software solutions puts the industrial data to work.

Accelerating the journey

How can GE Digital support your Digital Transformation journey?

What are the outcomes that matter for your organization? What will your next step be? These are big questions for any organization operating in today’s rapidly changing environment.

Regardless of where you are in your digital transformation journey, GE Digital can help you take that next step with confidence. Together we can deliver solutions supported by our deep industry expertise, a 30-year legacy of digital transformation, the full family of GE businesses, and a focus on best practices that go beyond technology—extending to people and processes, too.

The next step is an important one. But you don’t have to take it alone. Contact us to learn more about GE Digital solutions and services that can help you build a more connected and responsive enterprise—and make transformation a reality every day.

GE Digital, Putting industrial data to work.